- Sector: Food company – Meat production

- Typology of work: Polyurea-based roof coating STARFLEX HR-S

- Substrate: Different substrates

WHO IS THE COMPANY?

The customer is one of the most important agricultural cooperatives for the production of Italian meat that links tradition and future, history and quality, counting breeders and agricultural partners between three Italian regions: Lombardy, Veneto and Emilia-Romagna.

The company, being located in a purely agricultural area, has always invested in respect for the environment, in the improvement of production facilities and in the sustainability of production.

Aimed at expanding its offer, the company has invested to optimize its plants and production methods, obtaining important IFS, BRC, export U.S.A. certifications. and Japan.

EXISTING PROBLEMS

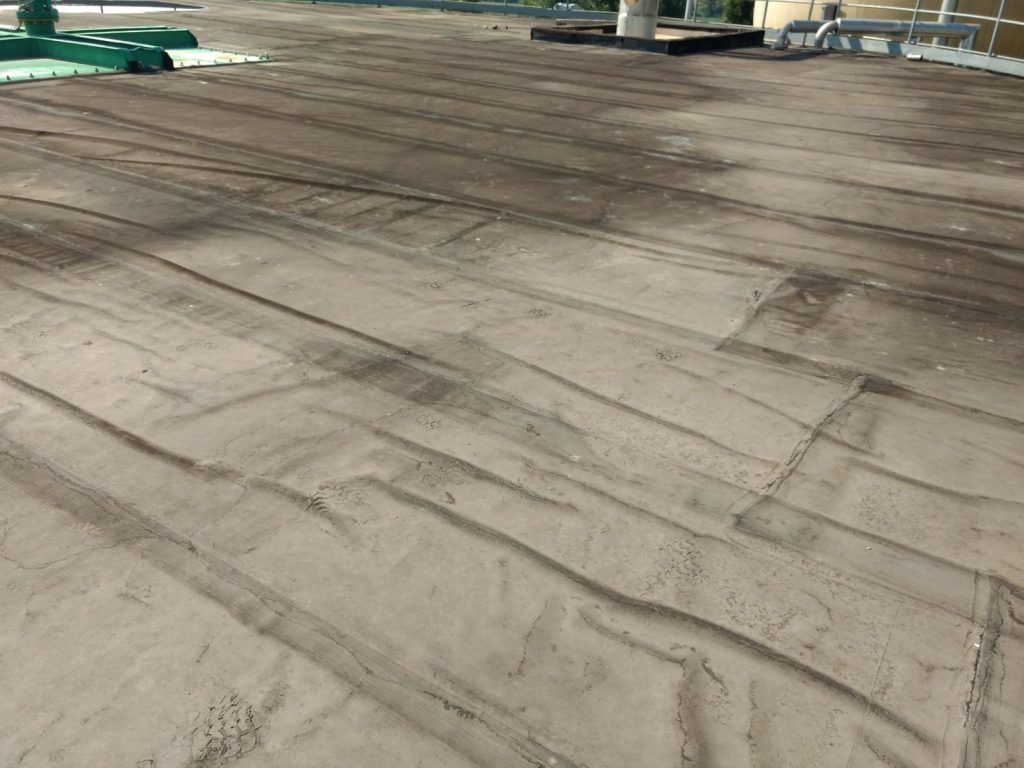

The production plant was subjected to water infiltration problems on the coating, due to the presence of different types of substrates, such as bituminous sheath, concrete and PVC blocks. The substrates have been damaged wear phenomena which have hindered the homogeneity of the existing roof, making it discontinuous and no longer guaranteeing water tightness.

Mpm WORK

Aimed to restore and protect the existing coating, mpm, together with its partner company, provided a totally seamless roof thanks to the use of the polyurea-based STARFLEX ON system applied by spray on the existing one. The intervention avoided the use of flames, adopting an elastic solution able to fill joints and cracks

The adopted system included a special sprayed liquid membrane which, once applied, formed a seamless waterproof roof, both horizontally and vertically, without joints or discontinuities and without the need for demolition or renovation. In this way it can be well adapted to different geometries and materials.

After an adequate cleaning and arrangement of the existing one, the first phase involved the application of specific primers for the various existing substrates. A two-component DUROGLASS FF4416 epoxy primer was used for the PVC membrane, which is very versatile and quick to apply. For the substrate in bituminous sheath, PRIMER 0230, one-component polyurethane with rapid adhesion and DUROGLASS P2 PRIMER for the substrate with concrete blocks, a special epoxy adhesion promoter with high mechanical characteristics.

A waterproofing coating with pure and soft STARFLEX HR-S polyurea was then applied without the presence of plasticizers or solvents. The application was performed through a high pressure bi-mixer misting system. The type of polyurea mpm spray allows to waterproof even coatings where there are points of discontinuity and complex geometries, such as skylights, installations, parapets, allowing to treat even the most difficult and hidden points and creating a continuous surface without joints.

SYSTEM APPLIED

Mpm system provides the following products:

- PRIMER PVC: DUROGLASS FF4416

- PRIMER GUAINA BITUMINOSA: PRIMER 0230

- PRIMER CLS: DUROGLASS P2 PRIMER

- IMPERMABILIZZANTE: STARFLEX HR-S

The work of Mpm, through the involvement of our specialized technical office, has allowed us to select the problems and to intervene, together with our applicator partner, offering a quick, certified and lasting result.