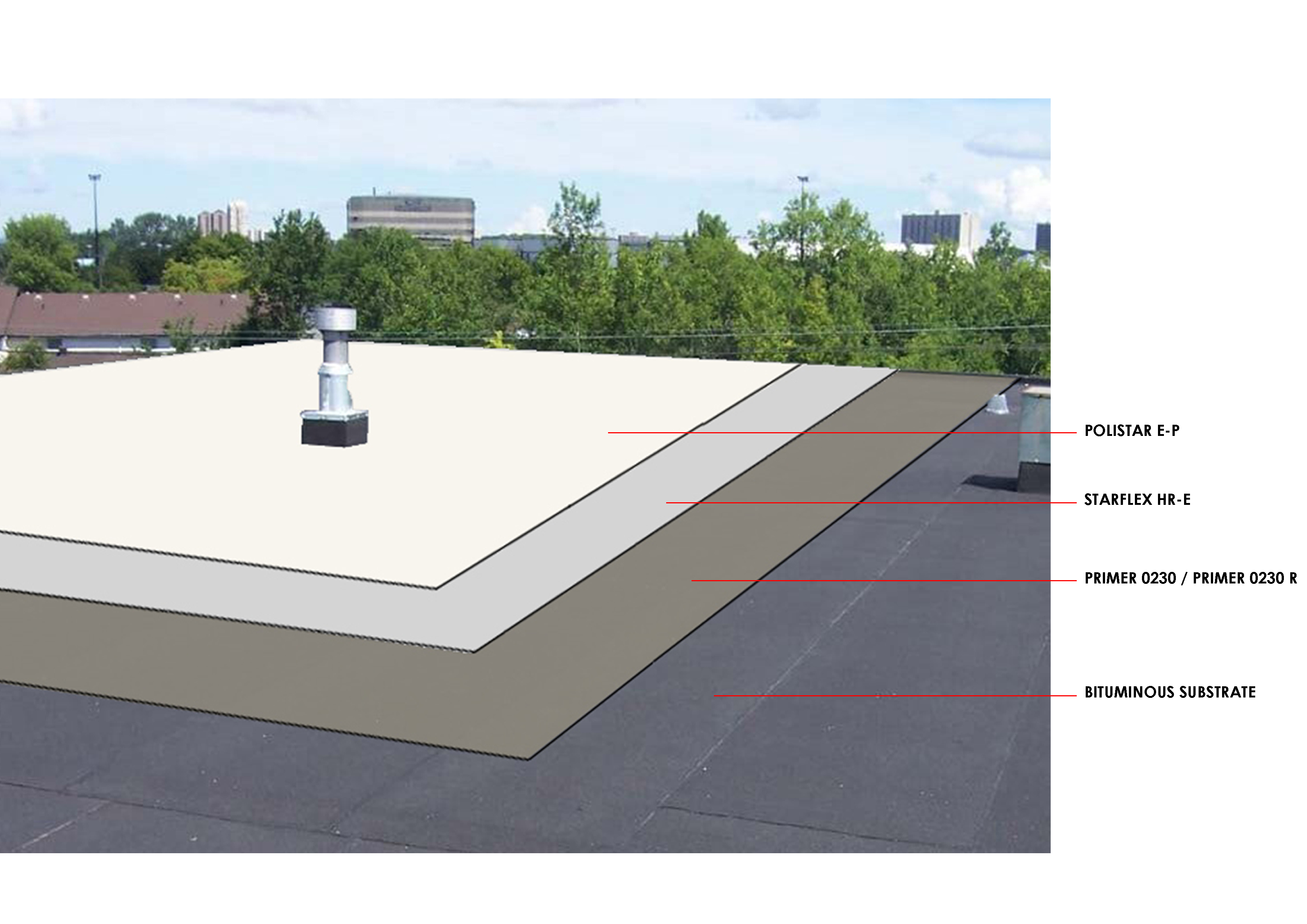

INDUSTRIAL ROOFING – WARM – EXPOSED – SOLAR PANELS

• Substrate to be treated must be free from debris and dust. Clean the substrate by either water jetting or air blowing and/or brushing.

PRIMERS:

• PRIMER 0230, moisture curing polyurethane, to be applied by means of a roller or brush or airless spraying device (with consumption of 100-150 g/m2). Over applica-tion time must be between 60 minutes and 16 hours according to environmental conditions.

A rapid version called PRIMER 0230 R is c available, allowing rapid over applica-tion time also in cold conditions (0°C) within 10 minutes. This version also helps removing traces of residual humidity from non absorbing substrates (morning dew). Does not help with water ponding or ice.

• STARCEMENT 5/A, water based epoxy primer to be applied by means of a roller, or brush or airless spraying device (with consumption of 100-150 g/m2 ). Over appli-cation time must be between 60 minutes and 16 hours according to environmen-tal conditions.

WATEPROOFING MEMBRANES:

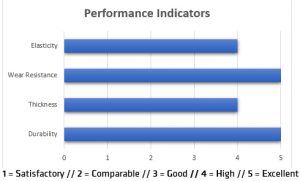

• STARFLEX HR-E, hybrid elastomeric polyurea system formulated with aromatic isocianates and special diammines, free from plastificants and solvents, or STARFLEX HR-S, fast hardening with a very fast attainment of the final mechani-cal characteristics, high resistance to the hydrolysis and the abrasion.

The products can be applied exclusively by spraying devices with two-component airless pumping units, equipped with a mixing gun, with a theoreti-cal consumption of 2,2-4,4 Kg/m².

The necessary equipment must also include pre-heating the separate compo-nents at temperatures of at least 65-75 ° C. The best results are obtained with pressures of at least 190 -210 Bar, material temperatures of 75 ° C with heated feeding pipes for the spray gun.

TOP COAT:

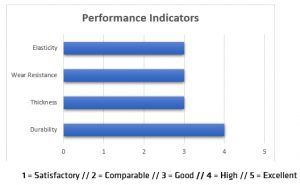

• POLISTAR E/P, two component elastic polyurethane based UV- resistant, anti-skid and wear resistant protective coating, one component elastic aliphatic polyurea based top coat for manual application at a rate of 0,15-0,25 kg/m² per coat.

The product for anti-slip can be added /charged with 0,1-0,3 mm quartz and or be broadcasted with 0,1- 0,5 quartz on the first of the 2 top coats.

When 2 coats must be applied do not let more than 48 hours between the coats.

• POLISTAR E/2, 2k polyurethane based uv- resistant, anti-skid and wear resistant protective coating, with a consumption of 0,150 Kg/m2.

• The over coating has to be applied within 3-4 hours maximum after the application of STARFLEX HR-E/STARFLEX HR-S.

• High elasticity and abrasion resistance, wear resistance with the ability of crack-bridging.

• Waterproofing, excellent chemical resistance and corrosion resistance.

• Substrate application temperature range: from -20°C a +40°C.

• Operating temperatures from -30°C to +100°C.

CONTACT US