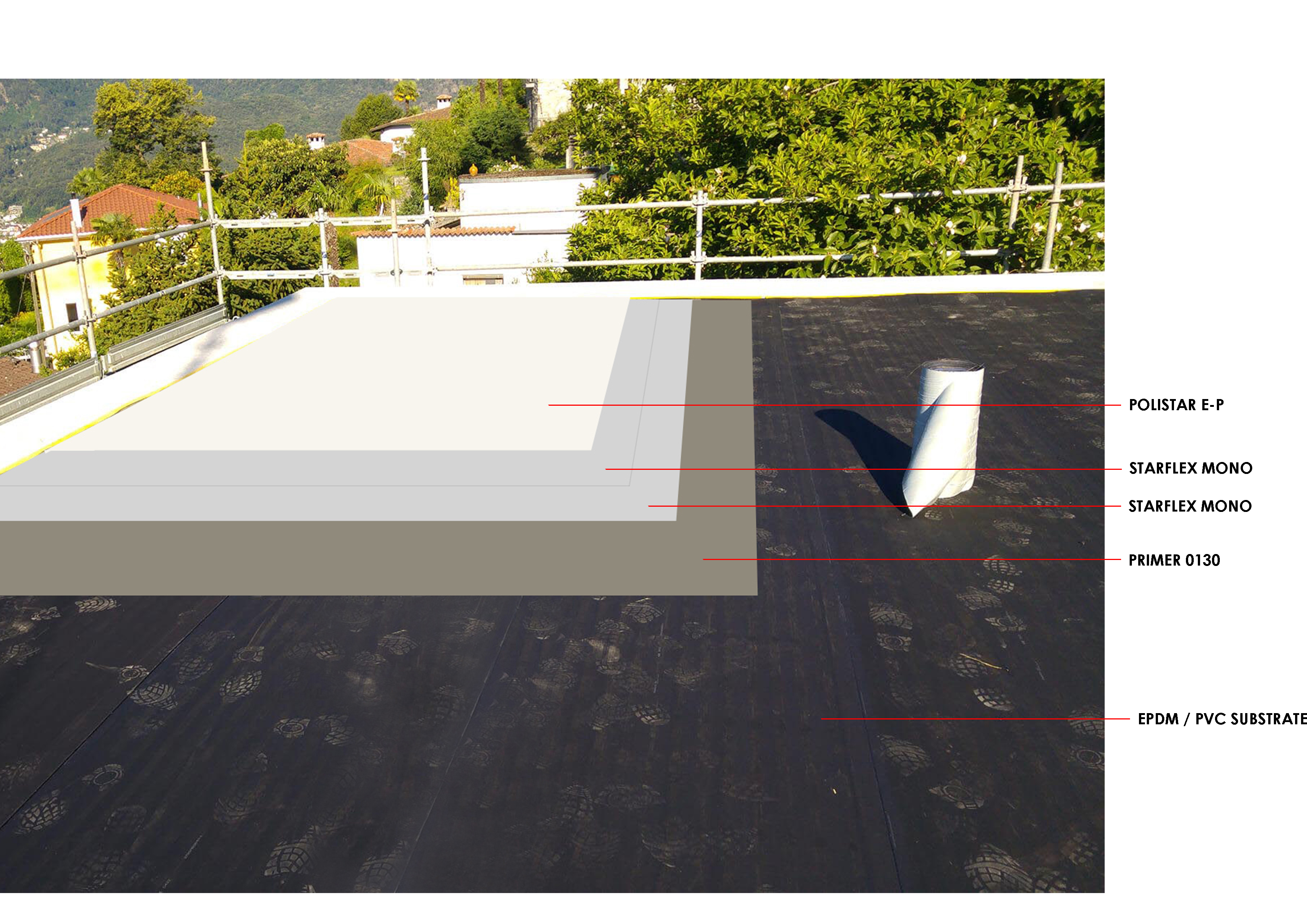

INDUSTRIAL ROOFING - COLD - EXPOSED - EPDM/PVC

• Substrate to be treated must be free from debris and dust. Clean the substrate by either water jetting or air blowing and/or brushing

PRIMERS:

• PRIMER 0130 with roll, brush or airless (with consumption of 100-150 g/m2 of 1:1 Diluted product with water).

Over application time must be between 60 minutes and 16 hours according to environmental conditions.

Adhesion promoter for polyurethane elastomers on concrete, metal, wood, asphalt, bituminous membranes, ceramics, PVC and EPDM.

Specially formulated to adhere different types of polyurethane membranes even with different hardening speeds.

WATERPROOFING MEMBRANE:

• STARFLEX MONO, one component moisture curing liquid polyurethane membrane. Application can be done by roller or brush or airless, spray 45:1 or 60:1 (pressure 130-150 bar and nozzle 0,021” or adjustable). Roller application is necessary for reinforced systems.

Consumption, is suggested at the maximum amount of 0,7 Kg/m2 per layer without reinforcement, and 1,0 Kg/m2 reinforced, even though thicker layers are achieva-ble.

• STARFLEX MONO TIX, (available also in the fire resistant grade, BROOF T4), one component thixotropic moisture curing liquid elastic polyurethane membrane, ready to use after mixing carefully with mixer at low r.p.m. Application can be done by roller or brush or airless, spray 45:1 or 60:1 (pressure 130-150 bar and nozzle 0,021” or adjustable). Roller application is necessary for reinforced sy-stems.

Consumption, even on vertical substrates is suggested at the maximum amount of 2,5 Kg/m2 per layer (without reinforcement), even though thicker layers are achiev-able. Roller application is necessary for reinforced systems.

Temperature of the product should be not lower than 20-22° C for spraying (best to check with a glass thermometer by dipping) otherwise the product could be too viscous. In cold environments mixing the product for 5 mins with a mixer can help rising the temperature of the product considerably.

• REINFORCED SYSTEM: use STARTEX NW or GM and impregnate with two layers of 1-1,5 Kg/m2 each and embed on the fresh layer the reinforcement. STARFLEX MONO TIX allows also wet on wet application ot the second coat immediately with the same consumption of 1-1,5 Kg/m2. The second coat can be applied also the next day as soon as curing allows the system to be walked over. Consider dry climates to be slowing down the curing of the product.

Important notice – Having enough product on the substrate through the first coat application is mandatory for avoiding the falling of the reinforcement (NW) due to low stickiness of the substrate.

TOP COAT:

• POLISTAR E/P, two component elastic polyurethane based UV- resistant, anti-skid and wear resistant protective coating, one component elastic aliphatic polyurea based top coat for manual application at a rate of 0,15-0,25 kg/m² per coat.

The product for anti-slip can be added /charged with 0,1-0,3 mm quartz and or be broadcasted with 0,1- 0,5 quartz on the first of the 2 top coats.

When 2 coats must be applied do not let more than 48 hours between the coats.

• Water vapour permeable, crack-bridging ability. Ideal for outdoor application. Can be over coated to improve U.V. protection.

• Applicable from +5°C to 35°C substrate temperature (R.H. <85%).

• Operating temperatures from -30°C to +80°C in air, (+200°C for short time).

CONTACT US