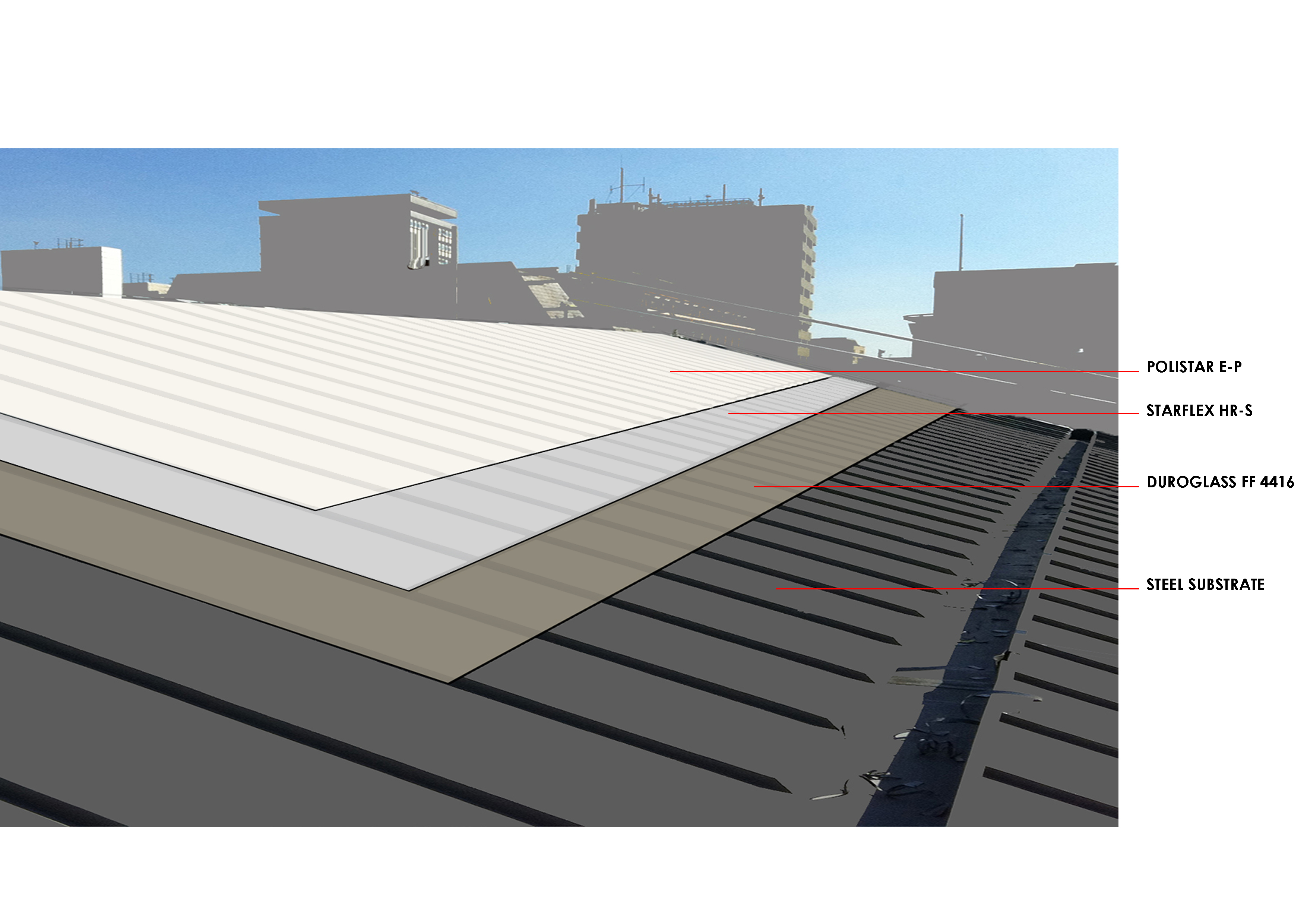

INDUSTRIAL ROOFING – WARM – EXPOSED – STEEL

• Substrate to be treated must be free from debris and dust. Clean the substrate by either water jetting or air blowing and/or brushing.

PRIMING:

• DUROGLASS FF 4416 is 2 component solvent based modified epoxy primer for concrete, steel, wood, plastic and tiles old coatings, and the product can be applied in multi-purpose applications on a wide range of substrates. It has long over application time (15 days).

Can be applied by brush or airless spray as presented or diluted with 5-10% of Diluente 21, with consumption of 0,200 Kg/m². For airless application, use 0.015”-0.021” nozzles at a pressure of at least 180 bars.

WATERPROOFING MEMBRANE:

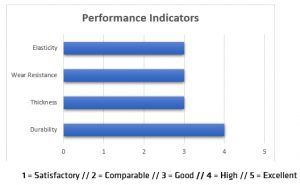

• STARFLEX HR-S, 2 components liquid soft polyurea waterpoofing, fast hardening with a very fast attainment of the final mechanical charac-teristics,hight elasticity and tenacity. Another waterproofing mem-brane is STARFLEX HR, rapid curing pure polyurea two-component 100% solids elastomeric with a theoretical consumption of 2,2-4,4 Kg/m².

STARFLEX HR-S can be applied exclusively by spraying devices (propor-tional hot spray) with two-component airless pumping units, equipped with a mixing gun. The theoretical comsumption is 2,5-4,0 Kg/m².

TOP COAT:

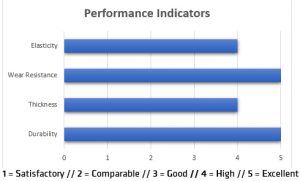

• POLISTAR E/P, two component elastic polyurethane based UV- resistant, anti-skid and wear resistant protective coating, one component elastic aliphatic polyurea based top coat for manual application at a rate of 0,15-0,25 kg/m² per coat.

The product for anti-slip can be added /charged with 0,1-0,3 mm quartz and or be broadcasted with 0,1- 0,5 quartz on the first of the 2 top coats.

When 2 coats must be applied do not let more than 48 hours between the coats.

• POLISTAR E/2, 2k polyurethane based uv- resistant, anti-skid and wear resistant protective coating, with a consumption of 0,150 Kg/m2.

• The over coating has to be applied within 3-4 hours maximum after the application of STARFLEX HR-S or STARFLEX HR.

• Fast Hardening with a very fast attainment of the final mechanical characteristics.

• Applicable also in vertical and ceiling.

• High elasticity, tenacity, resistance to puncturing, abrasion resistance and wear resistance with the ability of crack-bridging.

• Operating temperatures from -40°C to +90° C in the air.

CONTACT US