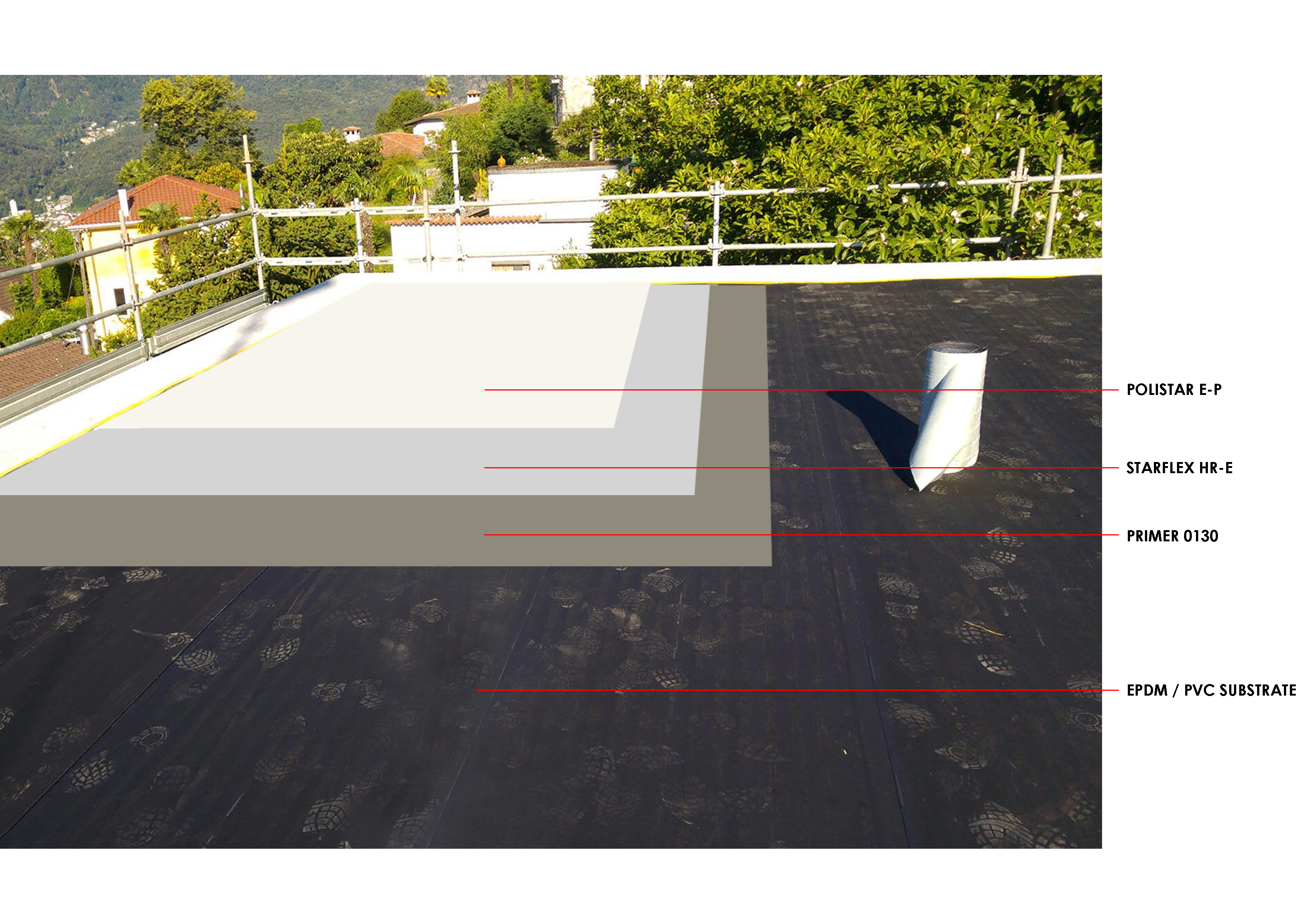

INDUSTRIAL ROOFING – WARM – EXPOSED – EPDM/PVC

• Substrate to be treated must be free from debris and dust. Clean the substrate by hydrojet/high pressure.

PRIMING:

• PRIMER 0130 with roll, brush or airless (with consumption of 100-150 g/m2 of 1:1 Diluted product with water).

Over application time must be between 60 minutes and 16 hours according to environmental conditions.

Adhesion promoter for polyurethane elastomers on concrete, metal, wood, asphalt, bituminous membranes, ceramics, PVC and EPDM.

Specially formulated to adhere different types of polyurethane membranes even with different hardening speeds.

WATEPROOFING MEMBRANES:

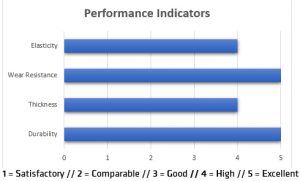

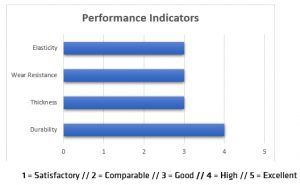

• STARFLEX HR-E, hybrid elastomeric polyurea system formulated with ar-omatic isocianates and special diammines, free from plastificants and solvents, or STARFLEX HR-S, fast hardening with a very fast attainment of the final mechanical characteristics, high resistance to the hydrolysis and the abrasion.

The products can be applied exclusively by spraying devices with two-component airless pumping units, equipped with a mixing gun, with a theoretical consumption of 2,2 Kg/m².

The necessary equipment must also include pre-heating the separate components at temperatures of at least 65-75 ° C. The best results are obtained with pressures of at least 190 -210 Bar, material temperatures of 75 ° C with heated feeding pipes for the spray gun.

TOP COAT:

• POLISTAR E/P, two component elastic polyurethane based UV- resistant, anti-skid and wear resistant protective coating, one component elastic aliphatic polyurea based top coat for manual application at a rate of 0,15-0,25 kg/m² per coat.

The product for anti-slip can be added /charged with 0,1-0,3 mm quartz and or be broadcasted with 0,1- 0,5 quartz on the first of the 2 top coats.

When 2 coats must be applied do not let more than 48 hours between the coats.

• POLISTAR E/2, 2k polyurethane based uv- resistant, anti-skid and wear resistant protective coating, with a consumption of 0,150 Kg/m2.

• The over coating has to be applied within 3-4 hours maximum after the application of STARFLEX HR-S or STARFLEX HR.

• High elasticity, abrasion resistance, wear resistance with the ability of crack-bridging.

• Water impermeabile, excellent chemical resistance and corrosion resistance.

• Substrate application temperature range: from -20°C a +40°C, dew point of > 5°C (in the absence of condensation).

• Operating temperatures from -40°C to +90°C on the air.

CONTACT US