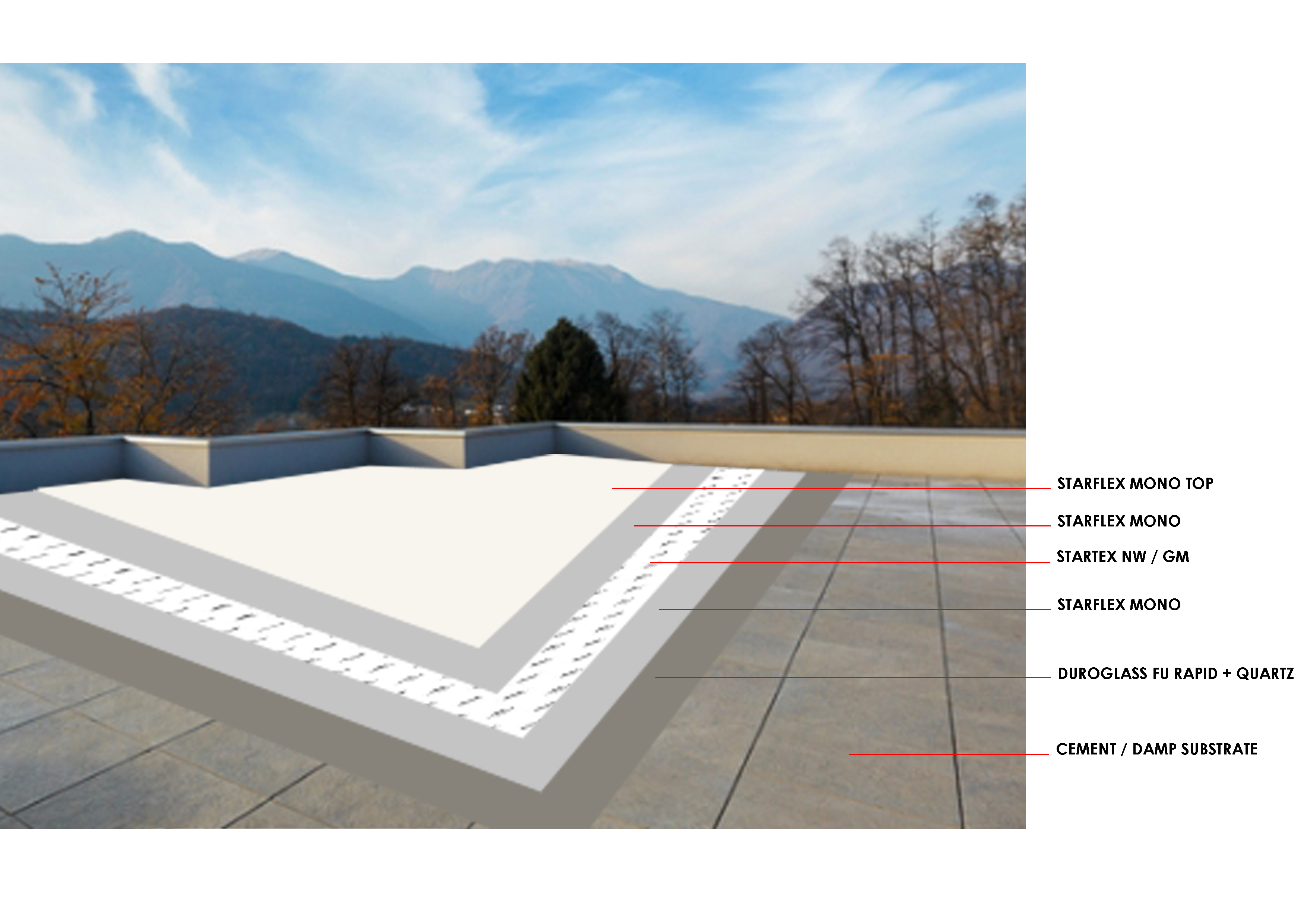

INDUSTRIAL ROOFING - COLD - EXPOSED - DAMP SUBSTRATE

• Substrate to be treated must be free from debris and dust. Clean the sub-strate by hydrojet/ high pressure/air blowing or brushing.

PRIMERS:

• DUROGLASS FU BIANCO TIX, water based 3 component modified epoxy. DPM primer designed for gaining adhesion on humid substrates up to 10 bar of back-pressure.

Solves humidity problems allowing safe application for all kinds of floorings. Overcoating 24 hours at 20° C, 75% RH with a consumption rate is 0,500-0,600 kg/m².

Can be used for scratch coats or roller applications. Low VOC.

• DUROGLASS FU RAPID, water based rapid 2 component modified epoxy DPM primer designed for gaining adhesion on humid substrate up to 10 bar of back-pressure.

Solves humidity problems allowing safe application for all kinds of floorings. Rapid curing allowing overcoating within hours even in cold temperatures 4 hours, 6° C, 75% RH.

Can be used for scratch coats or roller applications. Low VOC.

Consumption rate is 0,300-500 kg/m² per coat making sure that areas with greater absorption rate should be treated again.

WATERPROOFING MEMBRANE:

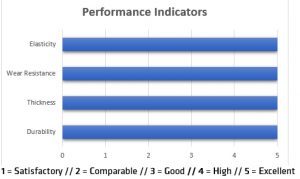

• STARFLEX MONO TIX, (available also in the fire resistant grade, BROOF T4), one component thixotropic moisture curing liquid elastic polyurethane membrane, ready to use after mixing carefully with mixer at low r.p.m. Application can be done by roller or brush or airless, spray 45:1 or 60:1 (pressure 130-150 bar and nozzle 0,021” or adjustable). Roller application is necessary for reinforced sy-stems.

Consumption, even on vertical substrates is suggested at the maximum amount of 2,5 Kg/m2 per layer (without reinforcement), even though thicker layers are achiev-able. Roller application is necessary for reinforced systems.

Temperature of the product should be not lower than 20-22° C for spraying (best to check with a glass thermometer by dipping) otherwise the product could be too viscous. In cold environments mixing the product for 5 mins with a mixer can help rising the temperature of the product considerably.

• REINFORCED SYSTEM: use STARTEX NW or GM and impregnate with two layers of 1-1,5 Kg/m2 each and embed on the fresh layer the reinforcement. STARFLEX MONO TIX allows also wet on wet application ot the second coat immediately with the same consumption of 1-1,5 Kg/m2. The second coat can be applied also the next day as soon as curing allows the system to be walked over. Consider dry climates to be slowing down the curing of the product.

Important notice – Having enough product on the substrate through the first coat application is mandatory for avoiding the falling of the reinforcement (NW) due to low stickiness of the substrate.

TOP COAT:

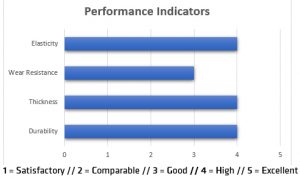

• STARFLEX MONO TOP, one component elastic aliphatic polyurea based top coat for manual application at a rate of 0,15-0,60 kg/m² per coat. The product for anti-slip can be broadcasted with quartz on the first of the 2 top coats.

The product for anti-slip can be broadcasted with quartz.

When 2 coats must be applied do not let more than 48 hours between the coats.

• STARFLEX MONO TOP 1, one component elastic aliphatic polyurea based top coat for manual application at a rate of 0,15-0,60 kg/m² per coat. The product for anti-slip can be broadcasted with quartz on the first of the 2 top coats.

When 2 coats must be applied do not let more than 48 hours between the coats.

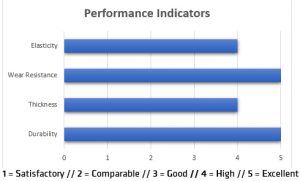

• POLISTAR E/P, two component elastic polyurethane based UV- resistant, anti-skid and wear resistant protective coating, one component elastic aliphatic polyurea based top coat for manual application at a rate of 0,15-0,25 kg/m² per coat.

The product for anti-slip can be added /charged with 0,1-0,3 mm quartz and or be broadcasted with 0,1- 0,5 quartz on the first of the 2 top coats.

When 2 coats must be applied do not let more than 48 hours between the coats.

• POLISTAR E/2, 2k polyurethane based uv- resistant, anti-skid and wear resistant protective coating, with a consumption of 0,150 Kg/m2.

• Water vapour permeable, crack-bridging ability.

• Ideal for outdoor application.

• High elasticity and high tensile strength and resistance.

• Applicable from +5°C to 35°C substrate temperature (R.H. <85%).

• Operating temperatures from -30°C to +80°C in air, (+200 for short time)

CONTACT US